The Blow-In Netting System is a top choice among insulation systems due to its impressive range of innovative, and state-of-the-art properties. If you are thinking about insulating your property, you should know that not all insulation is the same. Each system has its unique functions and applications. Discover why property managers of residential and commercial buildings often favor Blow-in netting.

Blow-in Netting Insulation System: What Is It?

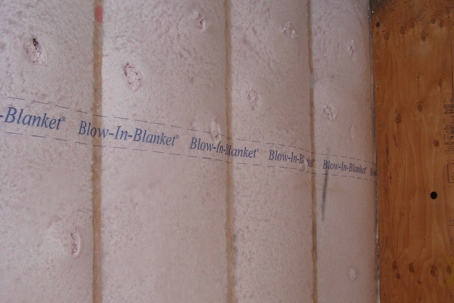

Blow-in Netting is an exceptional insulation system that utilizes specially manufactured fiberglass wool to insulate attics, walls, floors, ceilings, and other areas of a home. Unlike other insulation methods, Blow-in Netting forms a seamless "blanket" around obstructions like wires and pipes, ensuring a custom fit every time.

The system is supported by a proprietary fabric that delivers high performance and density. One of the key advantages of Blow-in Netting system is its outstanding thermal efficiency, providing a high R-value of 4.2 at a cost-effective rate. The Blow-in Netting system makes the initial investment worthwhile by significantly reducing heating and cooling costs.

In addition to its energy efficiency benefits, the Blow-in Netting system even reduces air gaps more than 68% better than traditional batting insulation. It provides excellent sound control and can be installed in any climate. The Blow-in Netting system is also highly durable and consists of at least 25% recycled materials, making it a long-lasting, eco-friendly investment.

Blow-in Netting system remains a popular choice for new and existing buildings with wood or steel frames. Its uniform density prevents settling issues that occur with other insulation systems. Besides, the Blow-in Netting system is naturally incombustible and does not support mold growth, even if moisture enters the wall cavity.

Blow-in Netting System Insulation is a certified system that meets the standard of Energy Star regulations for Grade 1 insulation. Homeowners should check with their contractors whether the blow-in netting system insulation they intend to install uses the specific insulation fabric and fiberglass fibers that are blow-in netting system-approved.

How Is Blow-in Netting System Different Than Fiberglass Batts?

Fiberglass batts consist of glass fibers created from heated sand and held together by adhesives, with modern versions using acrylic binders instead of formaldehyde.

Compared to Blow-in Netting system insulation utilization of pure adhesive-free fiberglass blown into a wall cavity behind a polypropylene fabric. This structure renders it inert and reusable, preventing moisture absorption and making it insect-resistant while warding off mold and rodents.

The fiberglass insulation is pre-cut and manually installed, causing itchiness due to adhesive exposure. Achieving proper density and filling voids might seem challenging, especially with irregular features. Contrarily, the Blow-in Netting system involves stapling polypropylene netting over the cavity and blowing fiberglass through a hose.

Unlike batt insulation, the Blow-in Netting system requires certified contractors to secure uniform density and custom-fill the cavity, enabling a more precise and effective installation. For performance, fiberglass batts have an R-value ranging from R 2.9 to 3.8, with installation challenges often revealed through thermal imaging.

On the other hand, Blow-in Netting system boasts an R-value of 4.2 per square inch, offering higher insulation efficiency. Fiberglass is often used and cost-effective, with lower insulation costs but more potential drawbacks when poorly installed.

In contrast, BIBS insulation usually requires a slightly higher investment—typically costing 30% to 50% more than fiberglass batts. However, it justifies this expense by delivering a superior R-value, exceptional cavity filling, and excellent sound control. These traits make this insulation system regarded by building owners as a worthwhile investment.

Which is better blown-in insulation or batting?

Blown-in insulation is better than batting in many cases. However, some homeowners preferred fiberglass batting insulation due to its effectiveness, efficiency, and installation cost. Blow-in Netting insulation is often more suitable for addressing under-insulated walls and crawl spaces, making it the best choice for re-insulation projects.

Otherwise, reinsulating with standard fiberglass batts would necessitate removing the drywall to access the space between joists, a costly, messy, and time-consuming project.

What is the R-value of blown-in netting insulation?

The R-value of blown-in netting insulation is 3.2 to 4.2, depending on the material and installation location within the house. With its higher R-value, it surpasses fiberglass batt insulation in energy efficiency. BIBS insulation maintains a superior performance throughout its lifespan. As a result, it stands out as one of the most effective insulation options currently available in the market.

What Is Blow-in Netting Insulation Made Of?

Blow-in Netting insulation is manufactured with custom-designed blown-in fiberglass wool, ensuring a snug fit around pipes and other irregular features. This design provides excellent thermal protection and a high R-value.

It is also recognized as one of the most environmentally friendly insulation options due to its composition of at least 25% recycled material. Another component used in BIBS is cellulose, a nonflammable plant-based fiber that enhances a building's fire safety.

How to Install Blow-in Netting Insulation

The Blow-in Netting installation process is a specialized procedure handled by certified professionals. The Blow-in Netting attaches to the frame, facilitating the pumping of insulation into framing cavities through a blowing tube.

This streamlined process minimizes the mess associated with traditional methods while providing a high-density, tight fill. The following steps outline the process undertaken by insulation experts to ensure optimal performance and efficiency:

- Check personal protective equipment (PPE), such as respirators, safety glasses, and gloves, and wear it at all times during the installation

- Set up barrier to control the insulation process and prevent unwanted dispersion

- Use pneumatic blowing system to affix breathable fabric to wall cavity for a stable base

- Create precise hole in insulation fabric for effective cavity filling

- Insert tube into cavity bottom and systematically withdraw it during insulation for total coverage

- Pump fiberglass wool into netting using specialized blowing machines to create densely packed wall cavities

How to Remove and Dispose of Blow-in Netting Fiberglass Insulation

Homeowners should recognize the danger of inhaling Blow-in Netting fiberglass insulation and call a professional to ensure safe removal and disposal. The pros will refrain from using standard dumpster disposal methods. Instead, they will contact the local waste authority for guidance on how to dispose of Blow-in Netting insulation, which may involve a small fee at designated dump sites.

Blow-in Netting insulation experts follow these straightforward steps for professional removal and disposal:

- Insert vacuum remover’s hose into wall cavity before extracting breathable mesh loose fibers, minimizing exposure to airborne fiberglass

- Access attic and manually remove fiberglass insulation by rolling up and placing in bags, or use vacuum cleaner with HEPA filter for safe containment

- Dispose of insulation privately for a fee or drop off at specialized waste facilities like building materials disposal sites

Is Blow-in Netting Insulation Eco-Friendly?

BIBS insulation stands out as an environmentally friendly option due to its composition. The fibers used in Blow-in Netting insulation contain a minimum of 25% recycled materials, demonstrating a commitment to sustainability. The remaining 75% consists of newly manufactured insulation made from raw materials.

These raw materials, such as silica sand, limestone, and soda ash, are sourced from the Earth's crust, and their extraction and manufacturing processes have associated environmental impacts. Blow-in Netting insulation system creates minimal material waste, using only the necessary amount of fiber to fill the wall cavities, reducing waste.

In contrast, batting insulation frequently produces excess pieces that require discarding. Besides, at the end of its lifespan, old or soiled fiberglass insulation often cannot be recycled and ends up in landfills. On the other hand, the biodegradability of blown-in cellulose and sheep's wool insulation makes them more eco-friendly.

Is Blow-in Netting Safe for Humans?

BIBS system presents minimal health risks when properly installed and sealed within the wall cavity. The only potential concerns arise during installation or removal because tiny fiberglass fragments may become airborne, potentially causing skin irritation and rashes.

Wearing a respirator, long sleeves, and gloves is advisable to minimize discomfort when working with fiberglass insulation. The Blow-in Netting insulation system is free from formaldehyde, chemicals, binders, and inks, ensuring a safer environment. Blow-in Netting insulation offers excellent fireproofing properties, eliminating the need for flame retardants, like those used in spray foam insulation.

The Benefits of Blow-in Netting Insulation

As a superior insulation solution, Blow-in Netting insulation offers a comprehensive range of advantages for new and existing buildings. Consider the following benefits of the Blow-in Netting system:

1. Shields Against Moisture and Outdoor Pollutants

Blow-in Netting ensures the correct density of fiberglass-blowing wool to create a vapor barrier against moisture, outdoor allergens, pollutants, and pests. The fiberglass used in Blow-in Netting insulation does not provide a habitat for insects or absorb water, preventing mold growth.

2. Better Energy Efficiency

Blow-in Netting insulation boasts a higher R-value than batt insulation, resulting in better efficiency and increased utility savings

3. Improved Thermal Performance

Blowing insulation into any building enhances heat flow and cooling thermal performance, providing a more consistent and comfortable temperature.

4. More Flexibility

Blow-in Netting insulation can be installed in any climate, making it a versatile option for shifting environmental conditions. Building owners may also use it in new or existing buildings, making it a versatile choice.

5. Exceptional Durability

Blow-in Netting is a durable insulation solution and a rewarding investment. The densely packed nature of the fiberglass prevents fibers from slumping over time, maintaining stable thermal resistance.

6. Reduced Air Leakage

Blow-in Netting reduces air leakage, preventing the infiltration of outdoor pollutants and dust, thereby promoting a cleaner and healthier indoor environment.

7. Excellent Sound Resistance

The dense packing of Blow-in Netting insulation minimizes air gaps around structures like pipes, promoting effective sound reduction.

8. No Off-Gassing

The Blow-in Netting system is free from chemical treatments like formaldehyde, ensuring no off-gassing or harmful fumes in the home.

9. Superior Fire Safety

The fiberglass used in the Blow-in Netting insulation is incombustible, meeting ASTM C674 for smoldering combustion and ASTM E136 for non-combustion, enhancing the overall fire safety of a home.

Conclusion

Now that you know the benefits of a blown-in netting insulation system, you can decide whether this solution is best for your home. Insulate your home with Blow-in Netting by contacting the best insulation company. Call iFoam at (855) 935-4723 to book a free consultation today!